The UJ Consortium Members use accelerated life testing to assess the life expectancy of a Universal Joint with cable in service in the aggressive conditions of both coastal waters and the deep ocean at the maximum operating voltage. The Inverse Power Law is utilized to assess the High Voltage (HV) test level and duration to be applied to ensure a twenty-five-year cable system life at a given operating voltage.

Early cable systems contained few fibers (typically 4 or 6) and comprised comparatively short system lengths (linking only two countries), so the Universal Joints used in the systems were qualified for operating voltages of 6, 8 or 10kV. As span lengths (and the consequent number of repeaters) increased and the number of fibers (and consequent number of optical amplifiers per repeater housing) increased, so the required operating voltage has increased in order to power the greater number of optical amplifiers. The current default UJ operating voltage is 15kV subject to the limits of the individual cable, but some cables utilizing the Universal Joint technology have now been qualified for operating voltages of 18kV and 20kV. The Universal Joint can now accommodate 192 of the thinner Splice Encapsulations FPS-U-UJ/UC. Multiple joint constructions and extensive testing demonstrates that the existing procedures, equipment and joint components remain suitable at higher operating voltages, but it is even more important to construct the joint to the highest standard.

When constructing Universal Joints, it is vital that users operate a robust maintenance regime, maintenance and calibration of equipment and instruments following the manufacturer’s guidelines as well as ensuring the adoption of the highest standards of cleanliness of tools, equipment and workspaces. All of these are key to success, especially so at the higher voltages.

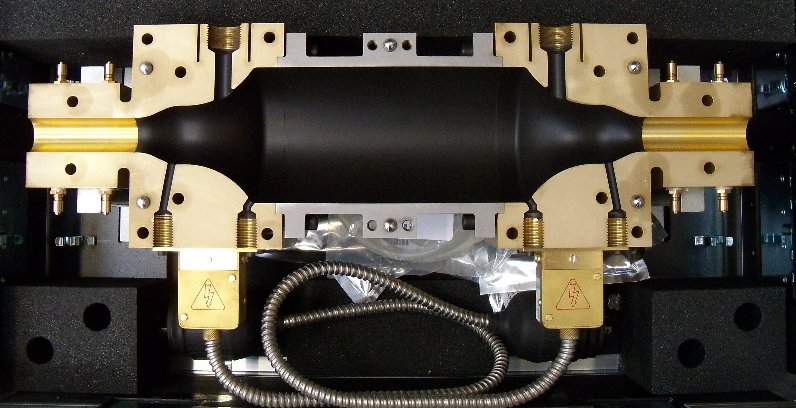

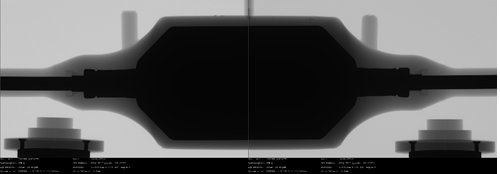

Jointing staff should be fully trained and qualified for constructing the particular cable and joint combination and should use the tools and equipment items specified in the UJCM. UJ Construction Manual instructions should be closely complied with. Completed moldings should be inspected against current UJ Construction Manual standards using the UJC X-ray Camera the DXr1. The UJ Consortium states that the most recent Common Component Kits (KITH9002) are used for jointing systems with higher operating voltages.

- In order to avoid built-in stress in the joint molding, it is necessary to carefully clean and assemble the Joint Housing Mold to prevent injectate leakage, however a small amount of flash is acceptable. The UJ Consortium differentiates between flash and leakage as follows:

Flash is a thin film of polyethylene injectate between the mold faces. - Leakage fills bolt holes and extrudes beyond the mold body.

Minimal flash is acceptable, whereas leakage is not and is an indicator that cleaning and adjustment or reassembly are required. Instructions on mold cleaning are shown in the Operation and Maintenance Manual for the UJ Mold. Full instructions for mold assembly and adjustment are shown in the Operation and Maintenance Manual for the UJ Mold Assembly Plate.

If there is a need for a Universal Joint cable combination to operate at a higher voltage than the current default operating voltage of 15kV, contact the UJ Consortium Coordinator or your UJ supplier. Full contact details for the UJ Consortium members are shown on the ‘UJ Consortium Contacts’ page.